Developing compost and liquid bio-fertiliser – trial now completed at the Agrimax Italian Pilot Plant

The newly constructed Agrimax pilot plant in the North of Italy (at family-run farm Chiesa) is starting to process unavoidable waste from tomatoes and cereals to produce a range of bio-based compounds for use in the chemicals, food-packaging and farming sectors. The products include lycopene, ferulic acid, cutin, and bio-fertiliser.

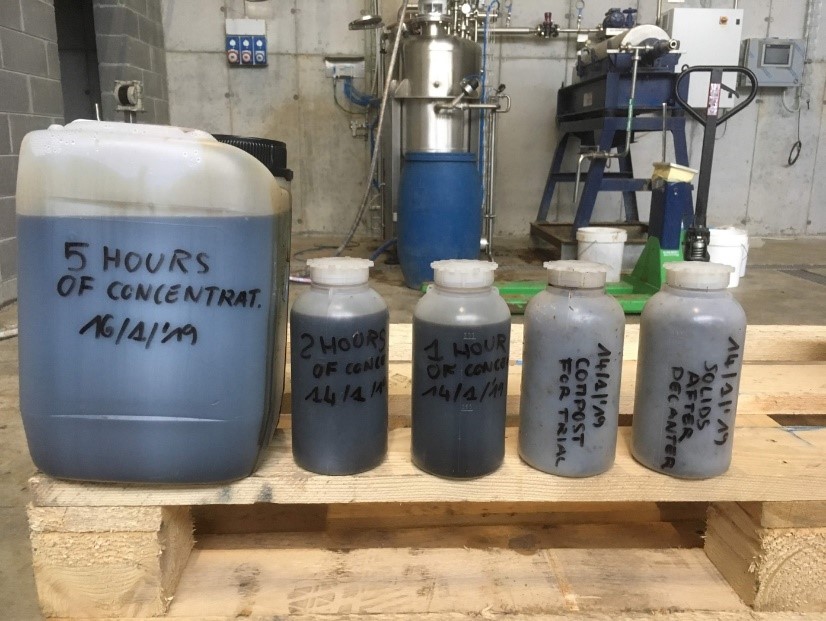

The first trial of the process to produce bio-fertiliser from tomato processing residues has been completed, generating 65 litres of hydrocompost (liquid concentrated bio-fertiliser) from 40 kg of conventional solid compost and 200 litres of water. The trial involved the following steps:

- The main reactor was loaded with water, chemicals and solid compost and the process was started.

- The reactor is brought to the correct conditions to encourage the transfer of valuable nutrients in the compost to the liquid fraction. Once this has been achieved, the solution is moved to decanter equipment to remove the solid.

- Once the solid fraction has been removed, the final step is to concentrate the liquid solution to the desired value.

- Samples from the first trial are being analysed and tested in order to determine the best conditions for the production of high-performing bio-fertiliser.

The Italian biorefinery is developing novel methods for coordinating and managing the provision of waste feedstocks to a biorefinery. The Italian pilot plant is designed to accept multiple feedstocks and an online stakeholder platform will coordinate the provision of waste from many regional producers. This will help maximise the use of the plant throughout the year and address seasonal and regional fluctuations, thereby maximising efficiency and profitability.

The Agrimax consortium combines the expertise of 29 partners from 11 European countries. The construction of the Italian pilot plant and the biofertiliser trials have required the input and expertise of the partners across the consortium, in particular:

- Universities and Research Centres have studied the process at a lab scale to define the main working conditions (UAL, SSICA, BPF, FRAUNHOFER).

- SMEs have been instrumental in the design, commissioning and communication of the pilot plant (CHIESA, EXERGY, IRIS, BIOVALE).

For further updates on the biorefineries keep an eye on our website and Twitter feed. If you are interested in converting your wastes or testing our products, please get in touch with us.

No Comments